Lyngso can be accessed via Holly to Shoreway and via Ralston to Shoreway.

First time at Lyngso? Familiarize yourself with our Lyngso Site Map ![]()

Landscape beautifully. Landscape sustainably.

Landscape Lyngso.

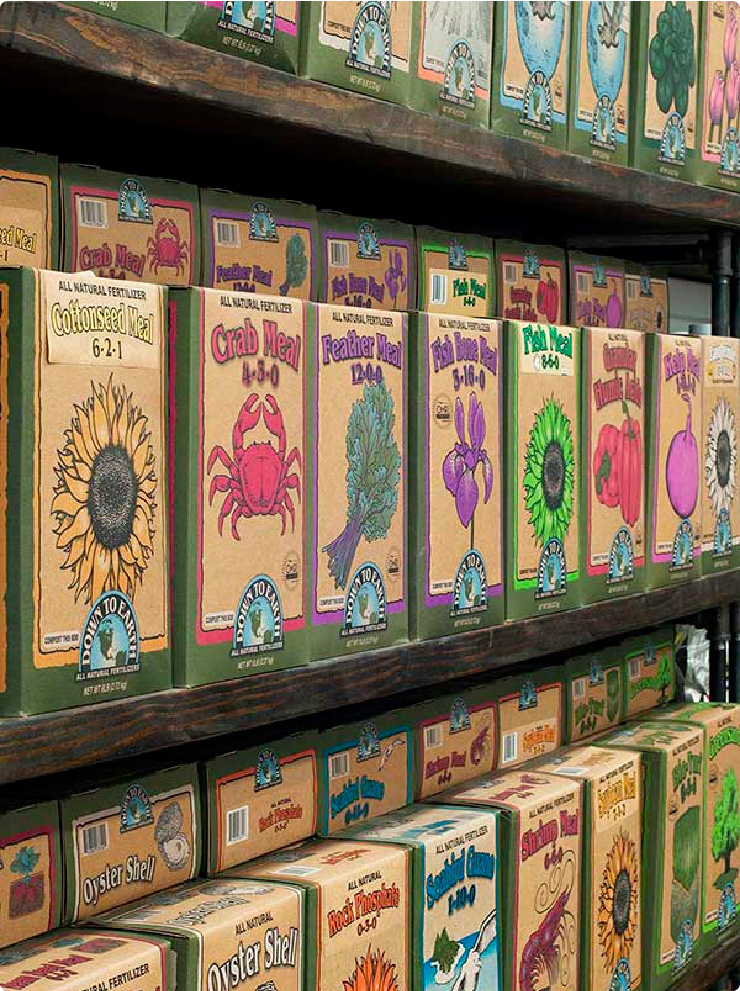

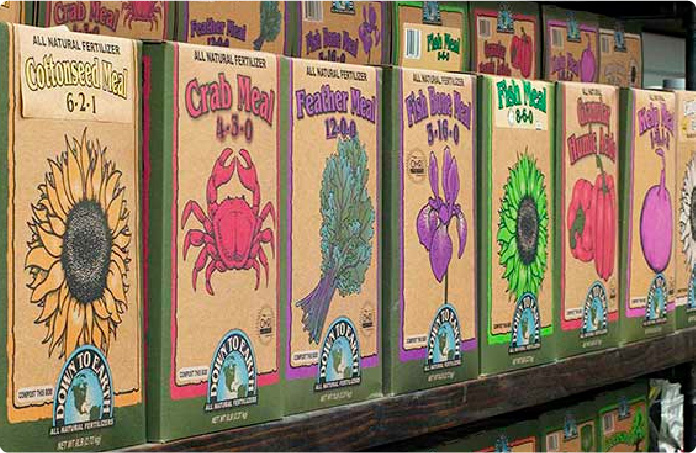

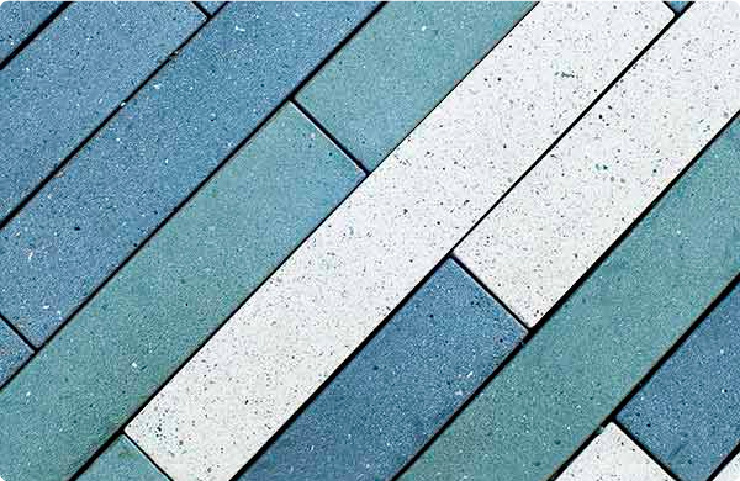

Whether you’re a contractor working on a large landscaping project, or a homeowner improving the soil in your garden, Lyngso has all the landscaping and gardening materials to make your corner of the world more beautiful.

Many of the people you’ll work with at Lyngso have been with us for over 20 years. Based in San Carlos, we are family-run and employee-owned business.

Browse Our Product Categories

Can’t find what you’re looking for? Search our products here

Helpful Resources

Upcoming Classes & Events